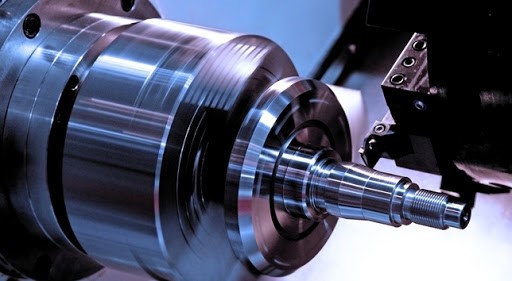

When you are the one responsible for the production of products, then you probably already know that CNC machining is a great option that you have. After all, it allows you to get the CNC parts that you need for your production processes without errors or delays. While you think that you are already applying the best CNC parts, the truth is that there is always room to improve their quality.

Ultimately, you are eager to improve the processes not only in terms of time but also in terms of quality. It is a must to ensure that you can not only maintain your customers as you can also get new ones.

Why Should You Use CNC Machining to Improve Production Efficiency?

- Improve the overall productivity

- Improve the surface quality of the part

- Improve the machining accuracy

- It may replace some processes such as grinding or electric machining

- It may bring significant economic benefits.

Top 4 Points to Enhance the Quality of CNC Parts

#1: Cutting Route Optimization:

When you are looking to enhance the quality of CNC parts, then you need to keep in mind that the CNC machining process always relies on optimizing the cutting angle. If you’re in the industry for some time, then you know that sometimes, you may find cutter marks on your CNC parts. The character of surface border curve in complex contoured product is the key point affecting the appearance designing quality of a product.

To make sure have a smooth and polished outlook and surface, the spare extension of the part always a perfect cutting point for you to apply. However, this may not happen at all in case you take the time to adjust or optimize the cutting of the cutter. The lower the speed used to cut the parts, the better and the smoother the parts will be.

#2: Correct Cutting Method in CNC Parts Processing:

When you are turning on the CNC milling machine, you probably already know that you have two methods: down milling and up milling. Overall speaking, when you use the first method, you will get a better finishing effect. This means that, whenever it is possible, this is the method that you should use to ensure that you get the best CNC milling parts.

#3: Use New High-Efficiency Tools:

CNC machining is always evolving and using new technology so you can get high-quality CNC parts. Not only the process should be observant, but also the choice of a new efficient tool. However, these will not work that well if you don’t pay attention to the other tools required, especially in what concerns with high-precision parts.

Overall speaking, you should be on top of the tools that allow you to be more accurate, faster, and yet precise, be safe when using the CNC machining, and even optimize cutting paths.

#4: Choose The Best Program for CNC Machining:

While you may already use a good CNC machining, it is essential to maintain it updated with the best program or software. After all, this is directly linked to the quality of the final parts.

The fact is that CNC machining requires a wide range of things to perform well. For accuracy and precision, a deep understanding of refining analysis process is also necessary. It demands highly-trained operators, a high level of programming, and also a high level of analysis.

Conclusion

As you can see, there are different things you can do to improve the quality of the CNC parts. If you have any requirement of CNC parts, you can contact us. At SOZN, you can check various examples of CNC parts online. Besides, you will also be happy to know that it provides two other high-precision metal parts services – the CNC turning and the CNC milling service.