Confirm that you’re analyzing water evaporation. This step entails sending a split sample to an outside laboratory to check the quantity of water given off from the sample. The two tools that can do that are a Karl Fischer-type tit-ration instrument or a moisture analyzer using a relative-humidity (RH) sensor.

Both devices are selective in discovering.

The samples must be verified to be giving just water from the moisture balance away. If you can’t correct the method to be sure water is being discharged. Then there is a moisture analyzer, not a tool.

The materials used,

Moisture analyzers:

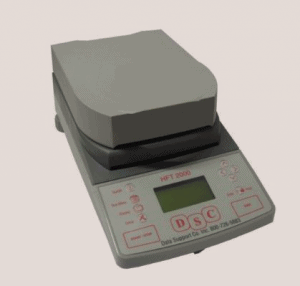

Moisture analyzers are the tools for determining the proportion of moisture in resin. The device is a sensitive equilibrium comprised inside an oven. The sample is inside, and mass is compared before and after the heating cycle to determine the percent moisture.

By sending out a split sample, You’ll have the ability to quantify and compare the results from your moisture balance to the sum of actual water to ensure that the material isn’t undergoing some other procedure producing a biased outcome.

Also Read: How To Choose Moisture Analyzer Tool

Vibrations:

Device A in Table 1 reveals a definite prejudice that should be decreased or eliminated to obtain accurate results. Instrument B indicates a small amount of bias that will provide a more precise outcome. The variation in dimensions shown by the percentage relative standard deviation (% RSD) also suggests that results from Instrument A will have much more difference than outcomes from instrument B.

It is helpful to get a sense of scale for what it is that you measure with a moisture balance. If you assume that your goal moisture for a resin is no higher than 0.02% and you also use a 40-g sample, you have to measure a difference in weight of 8 milligrams (0.008 g). That amount of water is the size of a pinhead. If your constraints are even lower than 0.02%, the amount you must measure reliably is even tinier.

Electromagnetic fields/static,

SENSITIVITY IS KEY

The detection limits should be low enough that you can measure to the specification levels of your stuff. That means that the instrument reading value is more unreliable at the level and highly variable if it is under your LOQ. That ultimately translates into more variability in the moisture of the material that is being processed.

Each of these factors implies that you need to read carefully and place it in the best location. Further more read this guide about moisture testing of plastics to make all your confusions clear.

The moisture analyzer is effective at detecting weight loss, irrespective of the kind of mass loss currently occurring. A legitimate moisture analyzer can detect only water loss by using the RH sensor, which can differentiate the difference between water and other volatile vapors being discharged from the sample. Table 2 shows that the sample is losing roughly 0.1% of its mass that isn’t water.

Air currents:

The six interferences lead to a bias in the result and may come into play. Something as pure from the hand of the individual pan would be enough to give you. Other things can come into play too. Oils transferred from oils onto the sample pan, or palms to the pan from its manufacturing process may be lost during the healing process. The moisture balance is in measuring that which melts off the sample and your pan indiscriminate. Any mass loss is interpreted, whether it is or not. You will have a great idea if your moisture analyzer has a problem with an outcome by running five repeats. Table 1 shows real data from a pair of moisture accounts tested in this manner.

The percent RSD is much more significant for its moisture analyzer due to the smaller sample size, making it more vulnerable to minor changes in the sample’s moisture content. Performing ten repeats can, variants in the examples shown, and a legitimate value for the general sample can be quantified. The moisture analyzer required much bigger sample size for testing.

Moisture balances:

Moisture balances discover changes other processes that have to do with the moisture level can bias the result due to the. Chemical reactions can result in either gaining or losing mass. Some additives may vanish from the plastic at higher temperatures as shedding moisture, and the instrument will translate that weight reduction.

When dealing with dimensions of tiny amounts, minor difficulties can cause massive effects. Some interferences may affect the instrument reading, including:

Step 1: Make sure that your moisture balance doesn’t have a prejudice or interferences. Run five repeat tests with a burden. The fat simulates the mass of your sample, but will not give any mass off when warmed. The outcomes of all the tests should ideally be 0, but there are numerous reasons it may be otherwise.

Step two: Characterize detection limitations. Among the most common methods of deciding the method detection limit comes from the U.S. EPA standard, 40 CFR 136, Appendix B. A variant of this method is explained here for illustration.

When characterizing your instrument, please consult with the CFR normal. The technique involves testing seven replicate samples the same way as in Step 1, except for each example. The amount added must be approximately three to five times the detection limit of this instrument. Twenty milligrams is an excellent place to start for moisture balances. The 20 mg can be weighed out with purchased solid criteria or accurately measuring out 20µl of water at a very exact syringe.

Evaluation:

It needs to be assessed. After of the information is collected. Ideally, your new results are at or near 0 milligrams so that there are no biases or interference’s inside the instrument or the procedure. Eliminated, and they ought to be identified to the best of your ability if there are biases. It may mean moving the moisture balance to another place or altering it, like using rubber gloves to avoid moving sweat or dirt.